- No need for pre-treatment: When using vapor-phase rust-preventive bags, metal products usually do not require complex surface pre-treatments. They can be directly put into the bags for rust protection, which greatly saves time and cost.

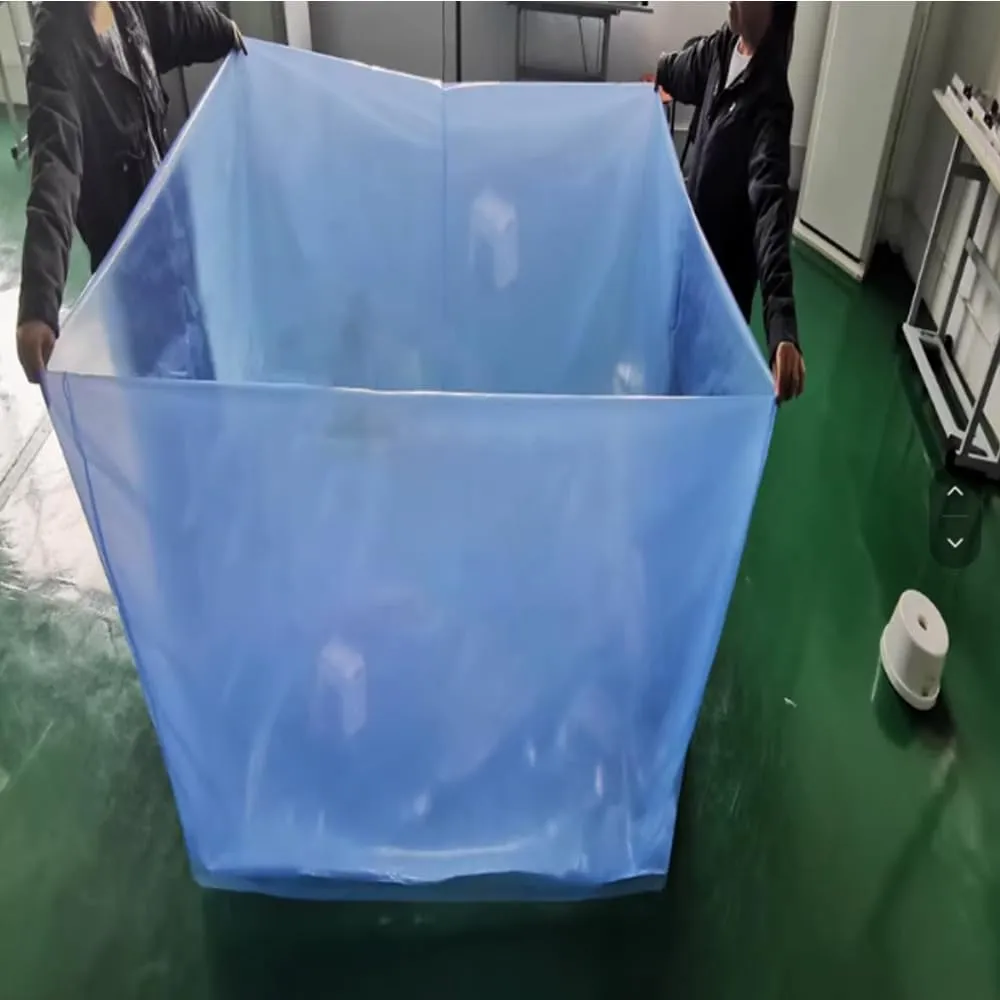

- Good visibility: Many vapor-phase rust-preventive bags are made of transparent or semi-transparent materials, which allows users to directly observe the condition of the products inside the bags. Without opening the bags, users can check whether there are any signs of damage or deterioration of the products.

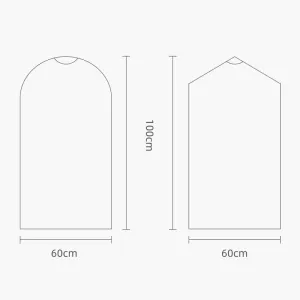

- Efficient space utilization: Vapor-phase rust-preventive bags are thin and light in texture and can be tightly packed according to the shape of the products, taking up little space. For situations where a large number of metal products need to be stored or transported, they can effectively improve space utilization.

- Easy to store and manage: The storage conditions for vapor-phase rust-preventive bags are relatively simple. They only need to be placed in a dry and cool environment. Moreover, they are easy to store in categories and label, which is conducive to inventory management and product traceability.

- Adaptable to various environments: Vapor-phase rust-preventive bags can maintain good rust prevention performance in different climatic conditions and environments. Whether in tropical regions with high temperature and high humidity or cold and dry regions, they can provide reliable rust protection for metal products.

Vapor corrosion inhibitor bags are fabricated using polyethylene material as the medium. Once proportioned with volatile corrosion inhibitors and other additives, they are processed via special extrusion machinery. This is a kind of anti-corrosion packaging material boasting excellent gasification and barrier characteristics. It falls under the category of a novel anti-corrosion packaging material and is particularly appropriate for the extended storage of metal products and corrosion protection during sea transportation.